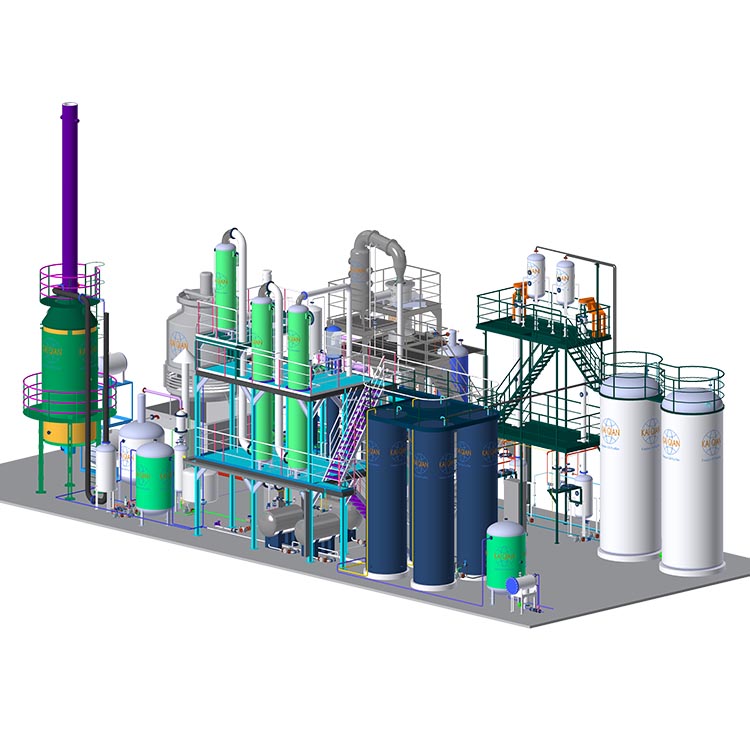

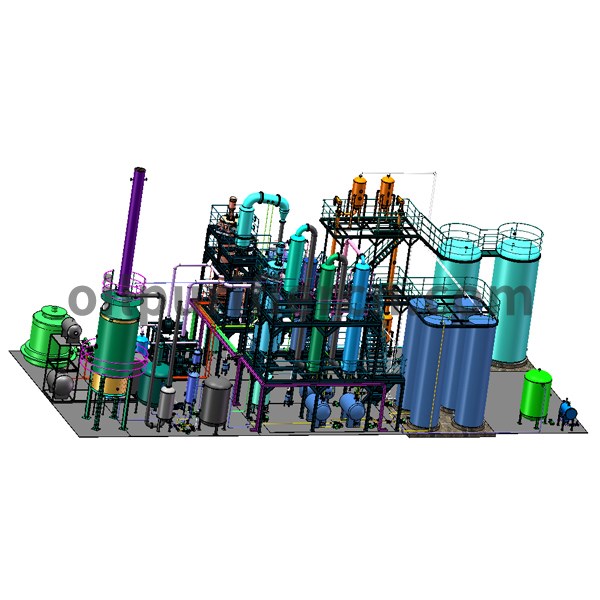

Ⅰ. Used Oil Refinery Plant Process Principle

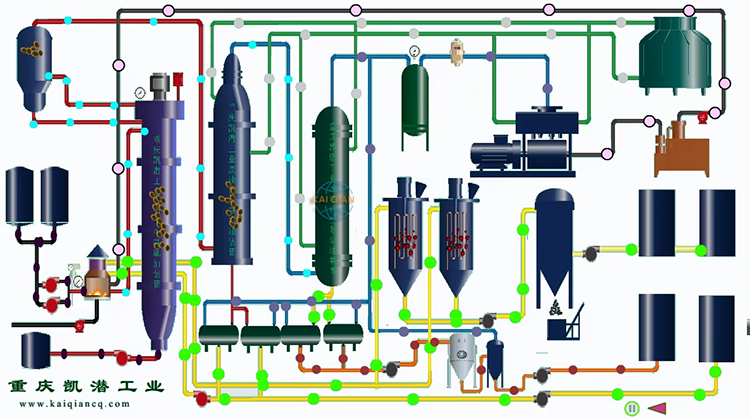

The principle of used oil refinery plant adopts the decompression atomization flash distillation technology, which is different from the traditional distillation relying on the boiling point difference separation principle. Used oil refinery plant adopts the decompression atomization flash distillation technology.

Ⅱ. Used Oil Refinery Plant Technical Features

(1) Pretreatment filtration of used oil refinery plant

Waste oil is analyzed by laboratory for grade analysis, and then filtered by heat exchange to remove large solid impurities, such as waste gloves, powder, waste screws, waste rags, etc. After filtering, the waste oil enters the storage tank.

(2) High vacuum dehydration of used oil refinery plant

Used oil refinery uses high-vacuum three-dimensional three - dimensional oil-water separation technology. The oil-water separation effect can reach 98%, and the water content in dehydrated lubricating oil is about 2%.

Ⅲ.Used Oil Refinery Plant Models and Parameters

Model designation | Unit | KTS-R2-5 | KTS-R15 | KTS-R20 | KTS-R30 | KTS-R50 | KTS-R100-200 | |||

Handling Capacity | T/D | 2-5 | 15 | 20 | 30 | 50 | 100-200 | |||

Working Pressure | Mpa | ≤0.5 | ||||||||

Working vacuum | pa | -5~ -20 | ||||||||

Temperature | ℃ | ≤350 | ||||||||

Working Noise | dB (A) | ≤85 | ||||||||

The power | V | 380-480V/50-60Hz Three-phase four-wire(Customizable as required) | ||||||||

Total Power | KW | 80 | 120 | 125 | 140 | 200 | 300-600 | |||

Cooling Water | M³ | 35 | 40 | 50 | 60 | 80 | ||||

Weight | T | 16 | 19 | 22 | 26 | 46 | ||||

Dimension | L | m | 15 | 17 | 17 | 25 | 45 | |||

W | m | 4 | 6.5 | 10 | 12 | 16 | ||||

H | m | 6 | 6 | 6 | 6 | 6.5 | ||||

Notification | 1.We can customize 150 -300TPD equipment as required 2.Diesel and natural gas heating method will be more economical. | |||||||||