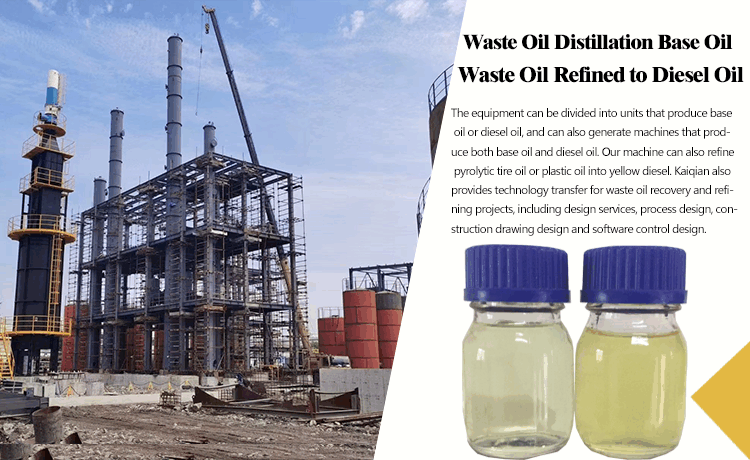

Waste Engine Oil Recycling Machine: Turning Waste into High-Quality Base Oil

The Waste Engine Oil Recycling Machine is a cutting-edge solution designed to recycle used engine oil into high-quality base oil. This environmentally friendly and cost-effective system is ideal for industries looking to minimize waste and maximize resource utilization. With advanced technologies for distillation, purification, and filtration, it ensures a sustainable process while delivering excellent oil recovery rates.

Key Features and Benefits

Efficient Oil Recovery

- Converts waste engine oil into high-purity base oil suitable for reuse in various applications.

- Achieves a recovery rate of up to 85-90%, significantly reducing waste output.

Advanced Distillation Technology

- Employs vacuum distillation to effectively separate impurities, sludge, and heavy hydrocarbons from the used oil.

- Operates at lower temperatures to ensure energy efficiency and minimize thermal degradation of the oil.

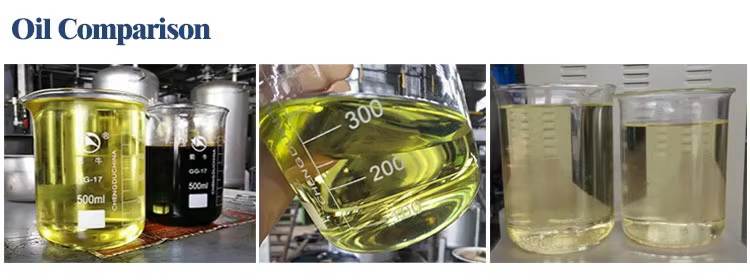

Integrated Purification System

- Multi-stage filtration removes solid particles, carbon deposits, and metallic impurities.

Special chemical treatment processes eliminate acid content, odors, and color impurities, restoring the oil to near-original quality.

Environmentally Friendly Design

- Closed-loop system ensures minimal emissions and prevents environmental contamination.

- Compliance with international environmental protection standards.

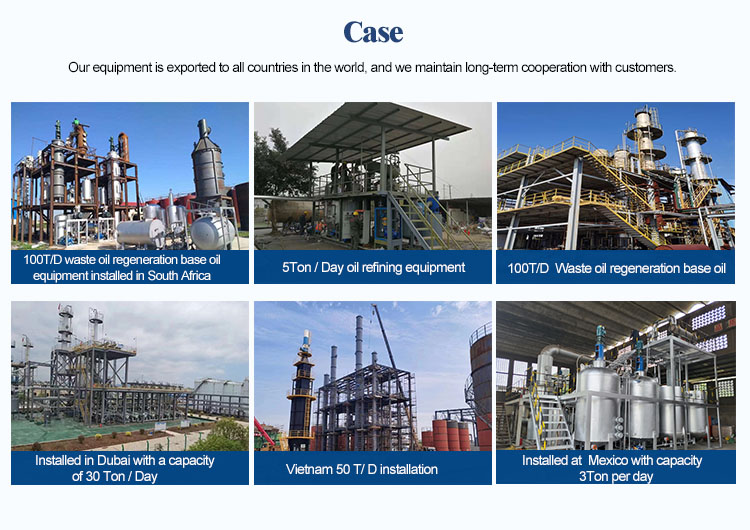

Customizable Capacity

Available in capacities ranging from 1 ton/day to 50 tons/day, catering to small, medium, and large-scale operations.

Automated and User-Friendly Operation

- Equipped with PLC control systems for automated operation, reducing the need for manual intervention.

- Real-time monitoring of temperature, pressure, and flow ensures safe and efficient operation.

Energy Efficiency

- Optimized heating systems and vacuum pumps reduce energy consumption, lowering operational costs.

Process Workflow

Pre-Treatment

- The waste engine oil is preheated and filtered to remove large impurities and water.

Vacuum Distillation

- Under controlled vacuum conditions, the oil undergoes distillation to separate light hydrocarbons, base oil, and residual sludge.

Purification

- The distilled oil is purified using chemical treatment and multi-stage filtration to achieve the desired quality and clarity.

Base Oil Production

- The final product is high-quality base oil that meets industrial standards, suitable for blending into lubricants or other applications.

Applications of Recycled Base Oil

- Manufacturing of new lubricants

- Blending with additives for industrial machinery

Production of hydraulic oil, gear oil, and transformer oil

Why Choose Our Waste Engine Oil Recycling Machine?

- Cost-Effective: Saves money by reducing the need to purchase new oil.

- Eco-Friendly: Promotes sustainable practices by recycling waste and reducing pollution.

- High Quality: Produces base oil that meets or exceeds industry standards.

- Reliable Support: Comprehensive after-sales services, including installation, training, and technical support.

Technical Specifications (Example)

| Feature | Specification |

|---|---|

| Processing Capacity | 10 tons/day |

| Base Oil Yield | 85-90% |

| Power Supply | 380V, 50Hz (customizable) |

| Control System | PLC with touchscreen interface |

| Distillation Technology | Vacuum Distillation |

| Purification Stages | Chemical + Filtration |

| Environmental Standards | Meets ISO9001 standards |

Get Started with Sustainable Oil Recycling

Contact us today for more information on how our Waste Engine Oil Recycling Machine can help you turn waste into valuable resources while protecting the environment. We offer tailored solutions to fit your operational needs and production goals.