Vacuum Oil Purifier Temperature Setting: A Key to Enhanced Oil Filtration Performance

Writer: Kaiqian Oil Purifier Release time:2024-12-12 14:40 Clicks:

A vacuum oil purifier is an essential device widely used in industrial settings, power plants, and various machinery to clean and purify oil. Its primary function is to remove contaminants such as solid impurities, water, and sludge from the oil, improving the efficiency and longevity of equipment. One of the most critical factors for the effective operation of a vacuum oil purifier is the correct temperature setting. The right temperature not only helps to improve the flowability of the oil but also enhances the removal of impurities. This article will explore how to properly set the temperature of a vacuum oil purifier for optimal oil filtration performance.

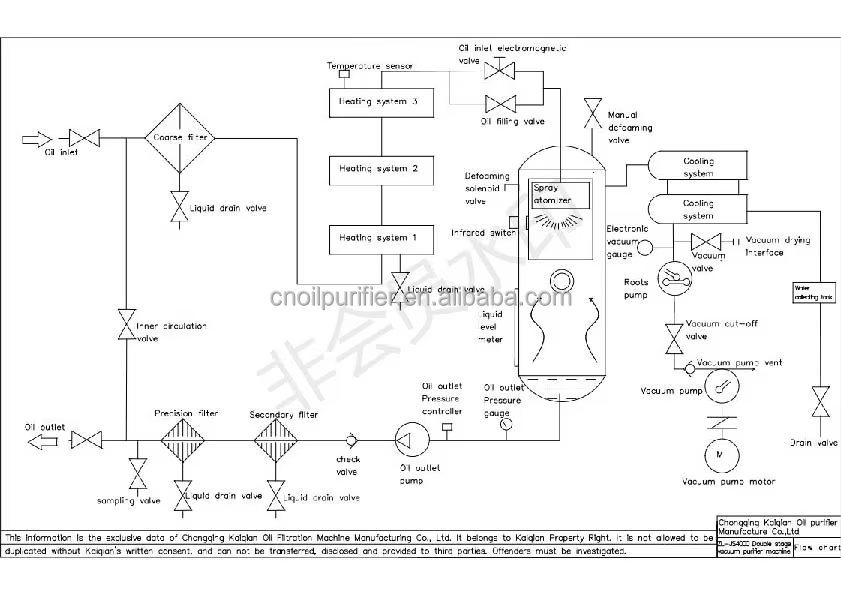

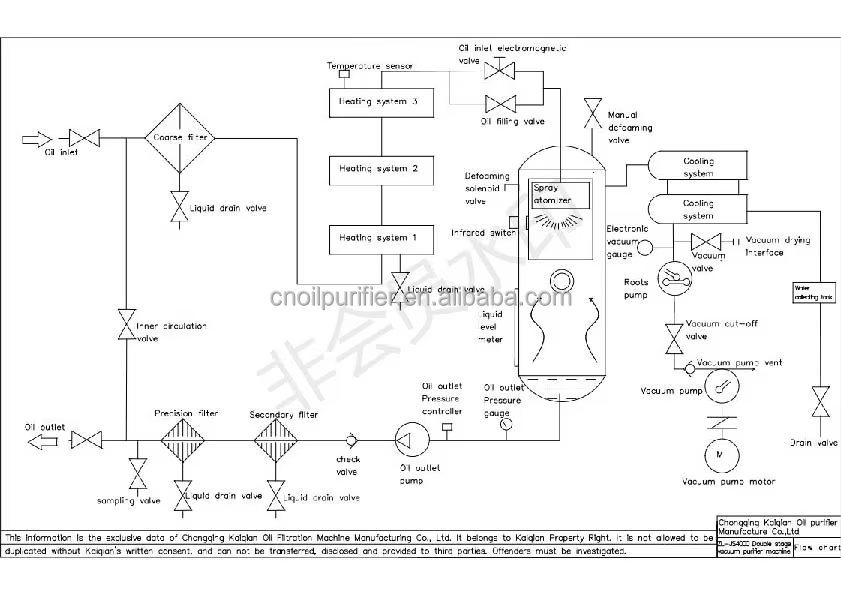

I. Basic Working Principle of a Vacuum Oil Purifier

The vacuum oil purifier works by filtering oil under a vacuum environment, removing impurities like solid particles, water, and other contaminants. The process is as follows:

Vacuum Pump Extracts Gas: A vacuum pump creates a low-pressure environment, which helps to remove air bubbles and moisture from the oil.

Oil Filtration: The oil passes through a filter element or mesh, where solid particles and other contaminants are trapped.

Oil Heating: To facilitate the evaporation of water and reduce the oil's viscosity, the vacuum oil purifier usually includes a heating system to maintain the oil at an optimal temperature during the filtration process.

The correct temperature setting ensures that the oil maintains suitable fluidity, helping separate water and impurities more effectively.

II. The Impact of Temperature on Vacuum Oil Purifiers

The temperature plays a crucial role in the efficiency of a vacuum oil purifier. Here are the main effects of temperature on the process:

1. Improving Oil Flowability

As the temperature of the oil increases, its viscosity decreases, which allows the oil to flow more easily through the filtration system. This is especially important for high-viscosity oils (such as transformer oil, lubricating oil, or hydraulic oil), where heating significantly improves the flow rate and accelerates the filtration process.

2. Accelerating Water Evaporation

Water is one of the most common contaminants in oil. Excessive moisture can degrade the oil and damage the equipment. The heating system in a vacuum oil purifier helps to evaporate the water in the oil more rapidly, improving the filtration effect.

3. Promoting the Separation of Impurities

At the correct temperature, the solid contaminants in the oil separate more efficiently. This allows the filter to capture more impurities, ensuring cleaner oil.

4. Avoiding Oil Degradation at High Temperatures

While heating can enhance the filtration process, excessively high temperatures can cause the oil to degrade or oxidize, reducing its lifespan and effectiveness. Typically, the oil temperature should be maintained between 60°C and 80°C (140°F to 176°F). Temperatures higher than 80°C may accelerate oil degradation, while lower temperatures can result in higher viscosity, decreasing filtration efficiency.

III. How to Set the Correct Temperature for a Vacuum Oil Purifier

1. Understand the Characteristics of the Oil

Different types of oil have different optimal operating temperature ranges. For example, transformer oils, lubricating oils, and hydraulic oils each have unique temperature requirements. When setting the temperature of the vacuum oil purifier, it is crucial to first understand the properties of the oil being filtered.

2. Set the Appropriate Heating Temperature

In general, the heating temperature for a vacuum oil purifier should be set between 60°C and 80°C. Temperatures above 80°C may cause the oil to oxidize and degrade, while temperatures below 60°C may result in high viscosity, making filtration slower and less effective.

3. Use a Temperature Control System

Modern vacuum oil purifiers are often equipped with advanced temperature control systems, allowing users to precisely adjust the temperature to meet specific needs. Using this system helps ensure that the oil is maintained at the optimal temperature throughout the filtration process.

4. Regularly Inspect the Temperature Sensors

The temperature sensor is a key component of the temperature control system. Regular checks are necessary to ensure that the sensor is functioning correctly. A faulty sensor could lead to inaccurate temperature regulation, affecting the efficiency of the oil filtration process.

5. Monitor Temperature Fluctuations

During the filtration process, the oil temperature may fluctuate. By monitoring the temperature in real-time, operators can adjust the heating system to prevent the oil from becoming too hot or too cold, thus ensuring a stable and effective filtration process.

IV. Common Mistakes in Setting the Temperature for Vacuum Oil Purifiers

1. Ignoring Oil Type Differences

Different oils have different ideal operating temperatures. A common mistake is using the same temperature setting for all types of oils, which may not provide optimal results. It is essential to adjust the temperature according to the specific oil type.

2. Setting the Temperature Too High

Some operators may assume that the higher the temperature, the better the filtration effect. However, excessively high temperatures can cause the oil to oxidize and degrade, which will reduce its effectiveness and lifespan. It is essential to maintain a balance and avoid over-heating.

3. Neglecting Temperature Control System Maintenance

The temperature control system is crucial for maintaining the correct temperature. Failing to regularly maintain and calibrate the system can result in incorrect temperature settings, reducing the performance of the vacuum oil purifier.

V. Conclusion

Proper temperature setting is critical to improving the performance and efficiency of a vacuum oil purifier. The right temperature ensures better oil flow, more effective removal of water and impurities, and prolongs the life of both the oil and the equipment. In practice, it is important to understand the characteristics of the oil, use an appropriate temperature control system, and monitor the temperature regularly. By avoiding common mistakes, operators can ensure the optimal functioning of the vacuum oil purifier and achieve high-quality oil filtration results.

简体中文

简体中文

English

English

Français

Français

Русский язык

Русский язык

Polski

Polski

日本語

日本語

ภาษาไทย

ภาษาไทย

Deutsch

Deutsch

Português

Português

español

español

Italiano

Italiano

한어

한어

Tiếng Việt

Tiếng Việt

Pilipino

Pilipino

بالعربية

بالعربية

বাংলা

বাংলা

IndonesiaName

IndonesiaName

ກະຣຸນາ

ກະຣຸນາ

Türkçe

Türkçe

简体中文

简体中文

English

English

Français

Français

Русский язык

Русский язык

Polski

Polski

日本語

日本語

ภาษาไทย

ภาษาไทย

Deutsch

Deutsch

Português

Português

español

español

Italiano

Italiano

한어

한어

Tiếng Việt

Tiếng Việt

Pilipino

Pilipino

بالعربية

بالعربية

বাংলা

বাংলা

IndonesiaName

IndonesiaName

ກະຣຸນາ

ກະຣຸນາ

Türkçe

Türkçe