Introduction of on-line filter device

The device is used in the hydraulic oil station system of lubricating oil station. The circulating filtration of oil field fluid and injection system can effectively remove impurities such as particles mixed in lubricating oil.

The device has the function of removing particulate matter and other pollutants in the oil to achieve purification and filtration.

1. System process and parameters

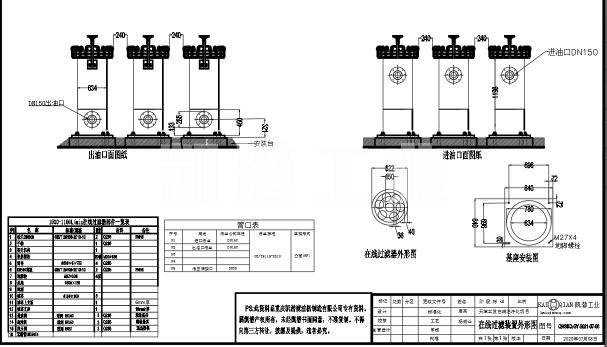

On-line filter installation is shown in the following figure. Through the switching of the oil inlet valve, the switching function of the process connection of the filter kettle can be realized, and the two filters can be used in series.

The inlet and outlet of the equipment are provided with a monitoring pressure gauge, and the top of the filter body 1 and 2 are equipped with a normal pressure relief valve to ensure that the equipment does not overpressure during use.

On-line filter installation parameters are as follows:

Limit pressure: 0.8MPa Working pressure: 0.5MPa

Tank material: Q235 or 304 stainless steel

Body size: mm, height: mm

Lid opening and closing form: quick opening structure

Filter media: oil, water, particulate matter

Filter material: hydrophilic and hydrophobic layer nanomaterials

2. Unit composition and function

The on-line filter is mainly composed of a filter kettle, a sliding system, a filter element, a pipeline and a valve group.

The overall appearance and piping connections are as follows

According to the process requirements, two sets of filter kettle are set up, one is ready and one is used, respectively, filter kettle 1 and filter kettle 2. According to the function required for filtration, the system is connected by pipes. The pressure of the large pressure system is 0.5MPa. The pipes and the filter kettle 1, the filter kettle 2 and the valve are connected with the pressure of 0.5MPa.

1. The filter kettle assembly is composed of cover, locking screw, kettle body support, layered filter element, barrel and connecting pipe.

2. The kettle cover is made of Q235 or 304 material. After processing, after polishing and local drawing, beautiful appearance.

3. The latch and locking screw are the locking mechanism of the kettle cover and filter bucket. After turning on the lock and locking screws, the kettle cover is bolted through the quick-opening structure. Considering the uniformity of force, multiple locks arranged evenly around the circumference can be turned and locked to ensure that the kettle body will not produce stress concentration.

4. The kettle body support is welded and fixed on the filter kettle, and is fixed on the beam of the sled body through the support, and is bolted to prevent the filter kettle from vibration and loosening.

5. The layered filter element is processed with special materials, which can realize the oil-hydrophilic and hydrophobic effect on oil and water. At the same time, after using the sintered filter element, the particles in the fluid will also be filtered together.

6. The filter body is arranged from outside to inside with a plurality of filter elements. The annular filter element achieves the filtering effect of oil and water through multiple separation and filtration, and the filtered fluid flows out from the middle, and is switched on or disconnected by the valve.

7. After the system connection pipe is connected to the two filters through the valve and through the component, install the gasket in place. Through the connection mode shown in the above figure, the series and parallel connection of filter kettle 1 and filter kettle 2 can be realized by switching the valve. The two processes switch and the filtered fluid can be discharged through a dedicated outlet.