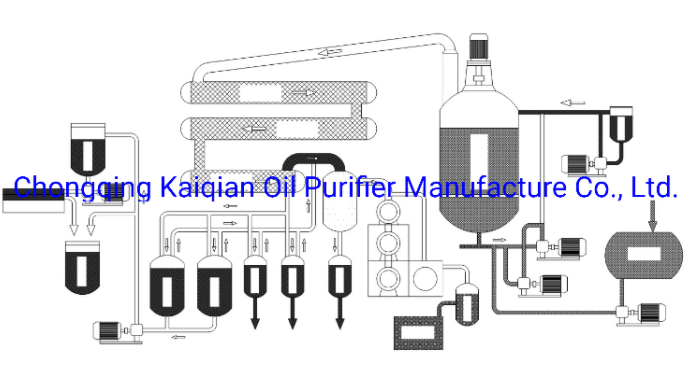

Ⅰ. Used Oil Recycling Machine Workflow

The waste oil containing impurities and moisture is heated to 80℃Cthrough a steam heat exchanger → to a filter to remove 5-15um impurities and then to an oil storage tank → the steam heat exchanger is heated to 100 ℃→ into a spiral spray atomization system The waste oil turns into a mist to a high-vacuum separation tower, and the water begins to evaporate. The oil mist forms a three-dimensional, multi-layered evaporation structure in the vacuum separation tower.

The hot water vapor separated from the vacuum separation tower enters the cold doubt. Most of the water vapor is condensed as water is stored in the water storage tank, and the water is discharged out of the machine after being purified by the coalescence separator. The purified lubricating oil is discharged through a bottom oil drain pump to complete a purification cycle.

Ⅱ. Used Oil Recycling Machine Five advantages

① The efficiency of regenerating the base oil is high, the process is simple, and the regeneration cycle is short;

② Adopting thin film evaporation process to improve evaporation efficiency and reduce energy consumption;

③ The entire system operates under high vacuum, which reduces problems such as high temperature cracking, polymerization, and equipment blockage;

④The waste mineral oil does not undergo the steps of acid washing, alkali neutralization, water washing, etc. During the production process, no acid residue and waste water are generated, secondary pollution is reduced, and good environmental protection effects can be achieved;

⑤ Residual kerosene and light fuel oil produced after regeneration can be sold as fuel, and resources are fully utilized.

Ⅲ. Used Oil Recycling Machine Models and Parameters

Model designation | Unit | KTS-R2-5 | KTS-R15 | KTS-R20 | KTS-R30 | KTS-R50 | KTS-R100-200 | |||

Handling Capacity | T/D | 2-5 | 15 | 20 | 30 | 50 | 100-200 | |||

Working Pressure | Mpa | ≤0.5 | ||||||||

Working vacuum | pa | -5~ -20 | ||||||||

Temperature | ℃ | ≤350 | ||||||||

Working Noise | dB (A) | ≤85 | ||||||||

The power | V | 380-480V/50-60Hz Three-phase four-wire(Customizable as required) | ||||||||

Total Power | KW | 80 | 120 | 125 | 140 | 200 | 300-600 | |||

Cooling Water | M³ | 35 | 40 | 50 | 60 | 80 | ||||

Weight | T | 16 | 19 | 22 | 26 | 46 | ||||

Dimension | L | m | 15 | 17 | 17 | 25 | 45 | |||

W | m | 4 | 6.5 | 10 | 12 | 16 | ||||

H | m | 6 | 6 | 6 | 6 | 6.5 | ||||

Notification | 1.We can customize 150 -300TPD equipment as required 2.Diesel and natural gas heating method will be more economical. | |||||||||