Ⅰ. Turbine Oil Regeneration Machine Usage

Turbine Oil Regeneration Machine is suitable for turbine oil turbine unit, hydraulic turbine unit. Through online or offline working, it can purifier coming degraded oil timely. TY-Q series Turbine Oil Regeneration Machine combine with vacuum drying separation, three -dimensional spiral atomization technology and precision filtration technology. After the treatment, the aged emulsified bad oil with dissolved water, gas, acid is treated, and meet new oil application standard. It is widely used in electric power, chemical industry, paper producing, petroleum and other industries, and can effectively ensure the safe operation of steam turbine lubrication system.

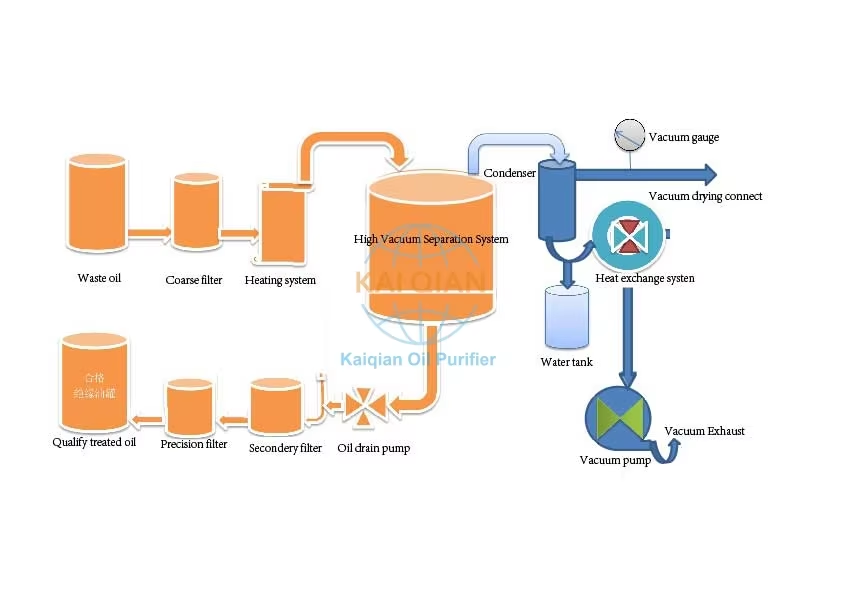

Ⅱ. Turbine Oil Regeneration Machine Working Principle

TY-Q Turbine Oil Regeneration Machine based on decompression separation and high precision mechanical filtration theory. Adopting molecular adsorption, vacuum drying, mechanical filtration technology, etc. Turbine Oil Regeneration Machine as one individual machine without any attached mechanical equipment. According to oil-water saturation temperature curve vacuum drying principle, to separate water quickly and effectively with three-dimensional and multi-stages oil water technology and multi-stages large flowing deep precision filtration technology.

Ⅲ. Turbine Oil Regeneration Machine Function

1. improve the cleanliness of lubricating system on Dilute Oil Station and oil tank, impurity and dewatering degassing and impurities removal.

2. It can remove not only 100% free water and 99.9% dissolve water, but also 100% free gas and 98% dissolve gas, and the ends oil will meeting the national using standard.

Treated Gear Oil Parameters

Items | unit | Treatment parameter | est Method |

Mechanical impurities | % | 无 | GB/T511 |

Demulsibility number | Min | ≤15 | GB/T7605 |

Moisture | Mg/L | ≤50PPM | GB/T7600 |

Acid value | mgkoH/g | ≤0.3 | GB/T264 |

Cleanness-degree | Grade | ≤6 | NAS1638 |

Filter precision | ≤3um | ||

Patent Automatic Vibration defoaming technology

| most suppliers use this kind of technology for defoaming, actually the truth is they defoaming by make the air into the vacuum evaporation tank, the air with moisture and impurities, which will make the oil be polluted secondary. If u like, i can send u this video, here i will give pics to show this, u see, when foam decrease, the vacuum decrease too, and here is a fabric, when defoam, it will be suctioned to the tank, which means here is air into the tank |

| This is our patent technology in almost 10 years experience in transformer oil filtration. The design like bellow. |

TY-Q Series Turbine Oil Recycling Equipment Technical parameters

TY-Q Series Turbine Oil Recycling Equipment Technical parameters

model item | unit | TY-Q20 | TY-Q30 | TY-Q50 | TY-Q80 | TY-Q100 | TY-Q150 | TY-Q200 | TY-Q300 | |

flow | L/min | 20 | 30 | 50 | 80 | 100 | 150 | 200 | 300 | |

working vacuum | Mpa | -0.08~-0.096 | ||||||||

working pressure | Mpa | ≤0.5 | ||||||||

working temperature | ℃ | ≤20~80 freely adjustable | ||||||||

power | V | 380-480V/50-60Hz Three-phase four-wire(Customizable as required) | ||||||||

electrical | kw | 24 | 30 | 36 | 42 | 48 | 54 | 60 | 72 | |

total power | kw | 26 | 33 | 39 | 46 | 53 | 66 | 74 | 84 | |

inlet/outlet pipe | mm | Φ25 | Φ32 | Φ32 | Φ42 | Φ42 | Φ48 | Φ48 | Φ60 | |

weight | Kg | 385 | 450 | 550 | 600 | 800 | 850 | 1000 | 1200 | |

Dimension | L | mm | 1350 | 1400 | 1450 | 1500 | 1550 | 1550 | 1700 | 1850 |

w | mm | 850 | 950 | 1100 | 1100 | 1150 | 1150 | 1450 | 1450 | |

H | mm | 1600 | 1650 | 1700 | 1700 | 1750 | 1800 | 1850 | 1910 | |

Note: The outline dimensions and the product weight is updating according to the improving technical. Pls take the real product as standard.(We can manufacture this machine with customer’s demands, we offer the closed type, conceal eaves style and the trailer type.)