I. ZL-JS Double-stage Vacuum Transformer Oil Purifier Usage

It is widely used in the oil purification treatment and vacuum hot oil circulation drying in the installation and maintenance of various large transformer equipment.. Not only use in Insulating oil purification treatment in 110KV-550KV transformer, but also applies to high-grade new oil, the high depth of processing imported oil.

Compared with the single-stage vacuum purifier machine, the machine increases the Roots pump pressurization system, secondary high vacuum separation systems and three-dimensional flash rapid evaporation system , it can quickly dewater, degas, and remove the acetylene, acid value and free carbon ,

The transformer oil breakdown voltage value will be higher after treated, It ‘s not only used for oil purifier but also as a separate vacuum source which have the function of vacuum drying and oil injection for transformer equipment.

Ⅱ. ZL-JS Double-stage Vacuum Transformer Oil Purifier Principle

The double stage Transformer oil filtration machine was designed according to decompression separation, precise filtration, Spiral spray atomization separation technology, molecular adsorption ,vacuum drying principle. The treated oil can meet the standard of the national standard.

Ⅲ. ZL-JS Double-stage Vacuum Transformer Oil Purifier Process

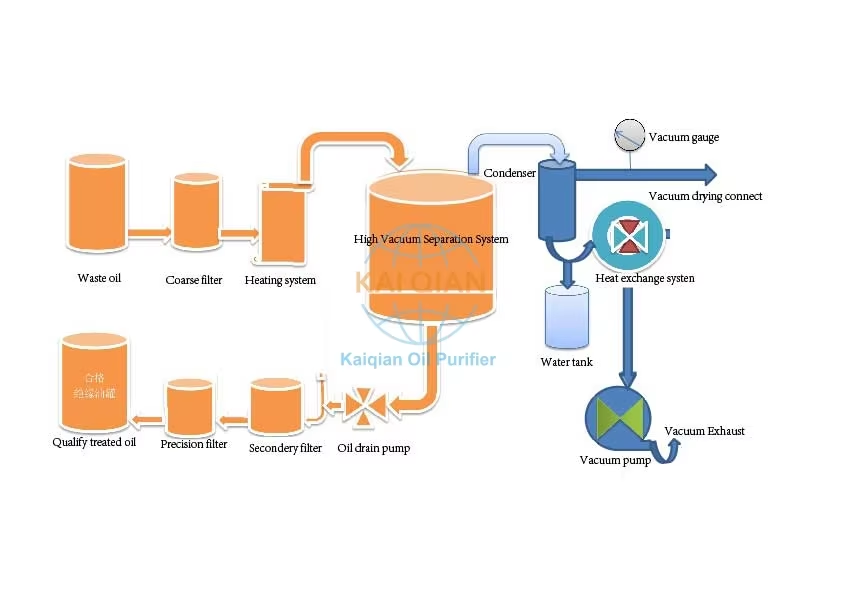

The oil to be treated passes through a strainer and enters the heater for heating, the heated oil will go through the semi precision filtration and arrives at the Spiral spray atomization separation system. The insulating oil turns into coarse mist and falls onto the reaction tower to enter the vacuum separation chamber.

The moisture begins to evaporate and the oil mist forms a three-dimensional, multi-layer evaporation structure in the tank, which can be purified through a short-term cycle. After dewater, degas, and impurity ,acid removal, the treated oil will go through the precision filtration to achieved the purifier circulation purpose.

The Water vapor molecules and the hot air are separate from the vacuum separation chamber enters the condenser ,Most of the water vapor is condensed into water and stored in a water tank. The hot air in the oil is cooled and discharged by a vacuum pump.

Ⅳ. ZL-JS Double-stage Vacuum Transformer Oil Purifier Function

4.1. Dehydration, degassing and impurity removal of 110-1100KV main transformer insulation oil .

4.2. Acetylene removal of 110-1100KV main transformer insulation oil .

4.3. Vacuum drying of 110-1100KV main transformer insulation oil .

4.4. It can remove not only 100% free water and 99.9% dissolve water, but also 100% free gas and 98% dissolve gas.

4.5. Customized parts: PLC, frequency conversion technology, trailer and so on.

4.6. Advantages and characteristics

double stage Insulation oil vacuum purifier machine process design, double stage efficient vacuum system, kaiqian unique Vacuum separation technique, it can quickly dewater, degas, and remove the acetylene, acid value and free carbon, colloid. increase oil limit Breakdown voltage value.

(a) Oil initial value: water content: ≤50mg / L, containing gas: ≤10% (volume fraction), the breakdown voltage: ≥25KV

(b) Secondary purification: water content:≤15mg / L, containing gas:≤0.1% (by volume), the breakdown voltage: ≥50KV (ball electrode).

(c) Three purification: residual moisture: ≤5-10ppm, residual gas≤0.05%, acetylene content :0, the breakdown voltage:≥60KV (ball electrode)

Note: water content and gas content measurements in accordance with relevant GB, DL or IEC standards.

Ⅴ. Transformer Oil Index by Double-stage Vacuum Transformer Oil Purifier

Items | Unit | Index | Testing method |

Mechanical impurities | % | NO | GB/T511 |

Demulsification value | Min | ≤30 | GB/T7605 |

Water Content | Mg/L | ≤5PPM | GB/T7600 |

Acid value | mgkoH/g | ≤0.3 | GB/T264 |

Cleanness | grade | Grade 6 | NAS 1638 |

Breakdown voltage value | KV | 55-65 | GB、DL Or IEC Standard |

Residual gas | ≤0.01% | ≤0.01 | The gas content measurement according to the standard of GB, DL and IEC |

Acetylene | Mg/L | 0 | The gas content measurement according to the standard of GB, DL and IEC |

Filter precision | 1um | ||

Ⅵ. Technical Parameters of ZL-JS Double-stage Vacuum Transformer Oil Purifier

Model Item | Unit | ZL-JS30 | ZL-JS50 | ZL-JS100 | ZL-JS150 | ZL-JS200 | ZL-JS300 | |

Flow Rate | L/min | 30 | 50 | 100 | 150 | 200 | 300 | |

Work vacuum | Mpa | -0.08~0.098 | ||||||

Work pressure | Mpa | ≤0.5 | ||||||

Work temperature | ℃ | 45-65 Adjustable | ||||||

Power supply | V | 380-480V/50-60Hz Three-phase four-wire(Customizable as required) | ||||||

Heating power | KW | 30 | 36 | 72 | 96 | 144 | 180 | |

Total power | KW | 33 | 40 | 76 | 102 | 152 | 190 | |

Diameter of intel&outlet | mm | Φ32 | Φ38 | Φ42 | Φ48 | Φ64 | Φ76 | |

Weight | Kg | 685 | 850 | 1200 | 1650 | 2300 | 3100 | |

Dimensions | Length | mm | 1100 | 1200 | 1450 | 1700 | 1750 | 1800 |

Width | mm | 950 | 1000 | 1150 | 13500 | 1450 | 1500 | |

Height | mm | 1450 | 1500 | 1700 | 2000 | 2000 | 2100 | |