Ⅰ.TYC Series Vacuum Oil Purifier with Trailer Usage

Trailer type vacuum oil purifier is widely used in electric power, petroleum, chemical industry and railway etc. It can purify oil in fieldwork with additional installation of a trailer, a damping spring steel plate, a brake and cornering lamp, this guarantee the safety and reliability when moving in fieldwork.

It is also used for hot oil circulation drying and oil purification when various large transformer equipment installation and maintenance. Purifying insulating oil in 110KV-330KV transformer, also suitable for high grade new oil, imported oil deep purifying.

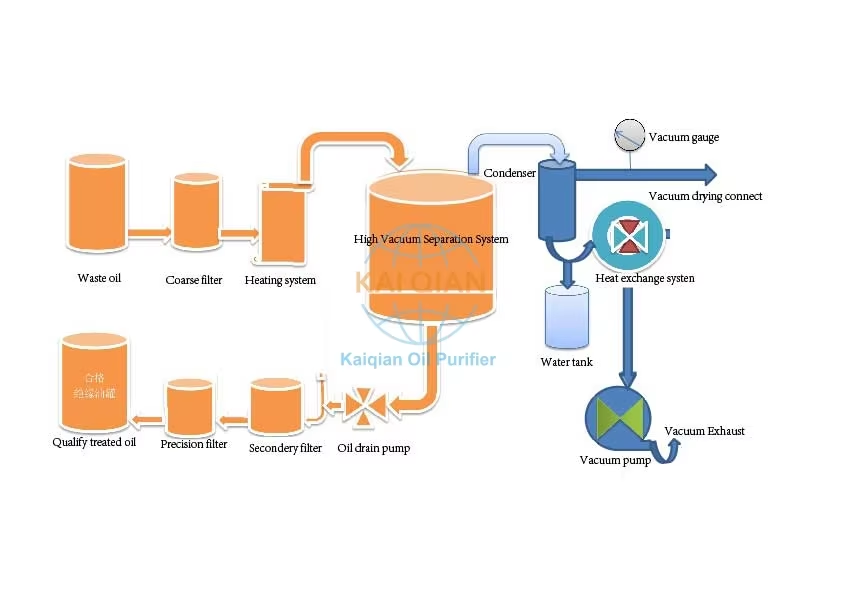

Compared with single stage oil purifier, this machine with additional roots pump pressure system, two high vacuum separation system and three-dimensional fast flash evaporation system. It can dehydrate, degas, remove acetylene, remove free carbon etc, the after treated oil with higher breakdown voltage. This is not only oil purifier machine, but also an independent vacuum unit for the drying of transformer equipment.

Ⅱ. TYC Series Vacuum Oil Purifier with Trailer Functions

2.1. Dehydration, degassing, remove impurities for 110-1100KV main transformer insulation oil .

2.2. Removing acetylene for 110-1100KV main transformer insulation oil .

2.3. Vacuum drying for 110-1100KV main transformer insulation oil .

2.5. Removing 100% free water and 99.9% dissolved water from oil, besides it can also filter out 100% free gas and 98% dissolved gas from oil.

2.6. customized according to customer needs; with PLC, frequency conversion technology, trailer etc.

2.7.Advantages and characteristics

This vacuum oil purifier with professional design, two-stage high efficiency vacuum system, kaiqian’s unique vacuum separation technology, it can remove water, acetylene, acid value, mechanical impurities, free carbon and colloid effectively and quickly, and improve the oil breakdown voltage like:

(a) oil initial value: moisture content: ≤ 50mg/L, the gas content: ≤ 10% (volume fraction), the breakdown voltage:≥ 25KV.

(b) secondary purification: water purification:≤ 15mg/L, the gas content: ≤ 0.1%: (volume), pressure value: ≥ 50KV (ball pole).

(c)thirdly purification: residual moisture:≤ 5-10ppm, the residual gas≤ 0.05%, Acetylene content is 0, the pressure :≥ 60KV (spherical polar) Note: the content of water and gas measurement method according to the GB, DL or IEC standard.

Ⅲ. Treated Oil Index by Vacuum Oil Purifier

Items | Unit | After treatment | Test method |

Mechanical impurity | % | No | GB/T511 |

Demulsification value | Min | ≤30 | GB/T7605 |

Water content | Mg/L | ≤5PPM | GB/T7600 |

Acid value | mgkoH/g | ≤0.3 | GB/T264 |

Cleanliness | grade | ≤6 | NAS 1638 |

Breakdown voltage | KV | 55-65 | GB、DL Or IEC Standard |

Residual gas | ≤0.01% | ≤0.01 | The gas content measurement according to the standard of GB, DL and IEC |

Acetylene | Mg/L | 0 | The gas content measurement according to the standard of GB, DL and IEC |

Filtration accuracy | 1um | ||

TYC Series Vacuum Oil Purifier with Trailer Technical Data

model items | unit | TY-C-30 | TY-C50 | TY-C100 | TY-C150 | TY-C200 | TY-C300 | |

Flow rate

| L/min | 30 | 50 | 100 | 150 | 200 | 300 | |

Working vacuum | Mpa | -0.08~0.098 | ||||||

Working pressure | Mpa | ≤0.5 | ||||||

Working temp. | ℃ | 45-65 adjustable | ||||||

Power supply | V | 380-480V/50-60Hz Three-phase four-wire(Customizable as required) | ||||||

Heating power | KW | 30 | 36 | 72 | 96 | 144 | 180 | |

Total power | KW | 33 | 40 | 76 | 102 | 152 | 190 | |

Pipe diameter | mm | Φ32 | Φ38 | Φ42 | Φ48 | Φ64 | Φ76 | |

Weight | Kg | 685 | 850 | 1200 | 1650 | 2300 | 3100 | |

Dimension | L | mm | 1100 | 1200 | 1450 | 1700 | 1750 | 1800 |

W | mm | 950 | 1000 | 1150 | 13500 | 1450 | 1500 | |

H | mm | 1450 | 1500 | 1700 | 2000 | 2000 | 2100 | |