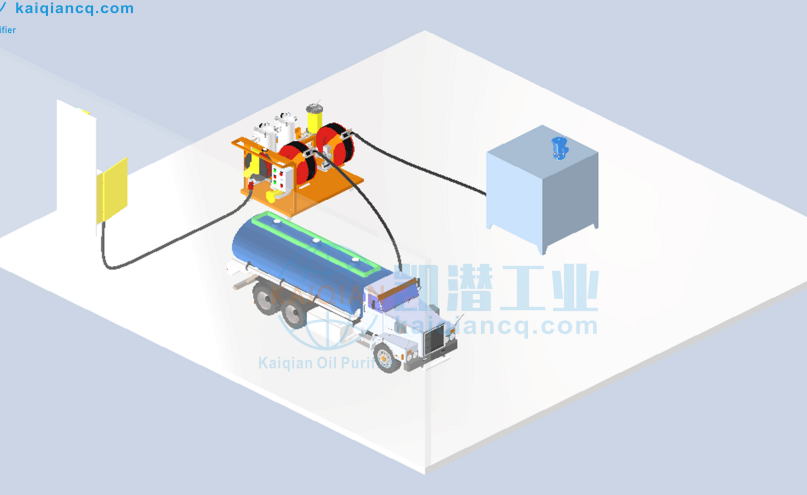

1、 Product Overview

The automatic pipe collection and line collection precision oil filter is developed for various oil station systems and is suitable for multifunctional oil filter trucks that handle complex oil products. It is widely used in lubricating oil, hydraulic oil, anti-wear hydraulic oil, compressor oil, air compressor oil, heat transfer oil, aviation hydraulic oil, diesel oil, etc. It can quickly remove impurities, moisture, etc. from the oil and improve the cleanliness quality of the oil.

2、 Working principle

2.1. The precision oil filter pump extracts the oil from the lowest point of the system oil tank, allowing the oil to pass through the filter element. The oil flows into the center hole of the filter element and returns to the oil tank through the bottom of the filter to complete a filtration cycle.

2.2. The pressure drop of the filter and the suction of dirt by the filter element can be observed through the pressure gauge installed on the top of the oil filter housing and the pressure controller to achieve the filter element blockage alarm prompt.

2.3. The oil outlet of the filter is located at the bottom of the filter. The filtered oil will return to the oil tank near the main system pump suction duct.

2.4. It must be noted that there is no oil pressure at the return point. If this condition cannot be met, please contact us.

3、 Technical characteristics

3.1. Adopting multi-stage microporous filtration technology, the precision oil machine can effectively remove free water from 0.5% of the oil while also filtering out 99% of mechanical impurities. The processed oil can meet the national standard for use.

3.2. The precision filter element for filtering hydraulic oil has a flux of 1-3um that is 5 times the design flow rate, which can fully meet the flow rate of the filtered oil and the sediment and turbidity amount of impurities, and can effectively remove various micrometer impurities.

3.3. Using wooden fibers, the professional filter element has high precision, layer by layer densification, and a large amount of dirt. The stainless steel filter element can be repeatedly cleaned and used, making cleaning the filter element convenient and fast, with a long service life.

3.4. Equipped with a pressure gauge (to monitor the pollution level of the filter element) to ensure that the filter element will not be damaged due to clogging and overpressure, reduce usage costs, ensure the safety of the filtration system, and remind the operator to clean or replace the filter element.

3.5. The precision oil filter oil pump adopts a helical gear type oil pump that has undergone precision machining and adopts a unique sealing method to ensure that the oil pump has no leakage, low noise, stable overall performance, and improved oil purification efficiency.

3.6. Standard wire slots are used for wiring inside the control box, and standard wire clamps are used for threading holes into the control box to prevent the incoming wires from falling off and scratching, ensuring neat wiring. The external wires of the control cabinet are protected by cable cables and corrugated hoses. The main electronic control components are selected from Schneider products in France; Or depending on the customer, Chint may decide. Circuit breakers, automatic overheat protectors, AC contactors, relays, buttons, and indicator lights; High quality electrical components ensure continuous and normal operation of the entire machine. Oil filter design, complete machine interlocking protection control; Alarm functions for overheating overload, phase loss, phase sequence, and overvoltage shutdown protection.

3.7. Filter overpressure protection; Designed with overpressure alarm shutdown protection (monitoring the pollution level of the filter element) to ensure that the filter element will not be damaged due to overpressure, causing secondary pollution to the oil, reducing usage costs, ensuring the safety of the filtration system, and reminding the operator to replace the filter element. Strictly speaking, the precision oil filter equipment has no other vulnerable parts except for the filter element, so it will not bring additional expenses to the enterprise.

3.8. The oil filter trolley is equipped with a circulating heater system, which improves the filtration efficiency of the oil after heating.

4、 Technical parameters of the oil purifier:

1. Equipment name: Automatic collection and purification machine

2. Specification and model: JL-G series

3 media: lubricating oil, hydraulic oil, aviation hydraulic oil, diesel, aviation kerosene, etc

4. Flow rate: 50-200L/min;

5. Power supply: 460-480VAC, 60Hz, 3Ph; 380 ± 10%, 50Hz ± 10%, 3-phase four wire system, neutral point directly grounded system;

6. Operating temperature: 0-50 ℃

7 Working pressure 0.5MPa

8 Oil pump: gear oil pump

9 Pump motor: 1.5KW

10 Pressure controller: PT-1.6 MPa

11 Installation method: mobile