Ⅰ. TY-G Series Hydraulic Oil Filtration Machine Usage

The filtration system widely use in Automotive Manufacturing, Aluminum Industry, Iron and Steel, hydraulic Press, hydraulic Oil, Anti-wear hydraulic Oil, Compressor Oil, Frozen Oil, pump truck hydraulic Oil, Engineering vehicle hydraulic Oil, and other unqualified Lubricating Oil purifier .

it is professional designed for all kinds of hydraulic oils, It can quickly remove impurities, moisture, gas, light hydrocarbon, acid value, improve the quality of oil, restore the unique performance of lubricating oil, and make the hydraulic oil emulsified seriously. Anti-wear hydraulic oil; after treatment becomes clear and transparent to ensure the operation of hydraulic system, power system, lubrication system.

Ⅱ. TY-G Series Hydraulic Oil Filtration Machine Working Principle

Vacuum hydraulic precision mechanical filtration, and taking use of molecular adsorption, vacuum drying, mechanical filtration, and many other technologies, without any affiliated equipment. Its three-dimensional and multi-level separation system take use of the theory of vacuum drying saturation temperature in oil and water, and also applied the multi-level, high throughput, and deep precisive filtration theory.

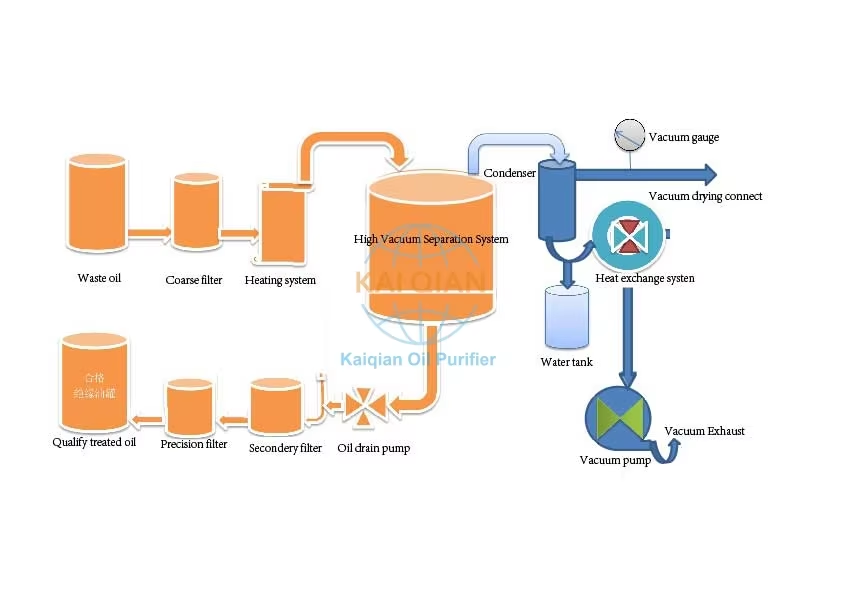

Ⅲ. TY-G Series Hydraulic Oil Filtration Machine Working Process

the oil goes through the first filtration and enters into the heating device, after heating, it goes into the second filtration and enters into the spiral spray atomization system. The insulating oil fall into the reaction tower when it becomes coarse particle and enters into the vacuum separation chamber, then the water begins evaporating, the oil mist becomes into the evaporation structure with the three-dimensional, multi-level evaporating in the tank. It can purify the oil in a short time. the oil without impurities, moisture, gas and acid will go through a precision filter to complete a clean oil working cycle. the steam and hot air separated from vacuum chamber will go into the condenser, most of the moisture will become the water and storage in the tank and drain out of the machine, the hot air will be cooled and exhaust from vacuum pump.

Ⅳ. TY-G Series Vacuum Hydraulic Oil Purifier Function

4.1 Improving the cleanness of hydraulic oil system anti-wear hydraulic system on Dilute Oil Station and fuel tank de-watering, degassing and impurities removal.

4.2 Hydraulic oil filtration system can remove not only 100% free water and 99.9% dissolve water, but also 100% free gas and 98% dissolve gas, and the ends oil will meeting the national using standard.

4.3 advantage of hydraulic oil vacuum purifier machine

4.31 Application of the advanced technology at home and abroad on similar equipment, so our devices are in the leading position on oil purifier and equipment performance. with the characteristic of high vacuum in working, fast speed in oil purifier and the high precision, etc.

4.32 It units the precisive filter and high dehydration, applied the advanced vacuum coalescence separation technology, which with the high dehydration, high ability in purifying low viscosity light turbine oil, hydraulic oil, antiwear hydraulic oil and gearbox oil. After the treating, the cleanness of medium will be promoted at level 6 ≥ DAS1638, the physical and chemical of the oil will keep the same, with higher lubricant effect, lower consumption, lower fee in working, better system setting, stronger continuous working ability and more suitable in online working.

After treatment oil quality parameters

Item | Unit | Treatment parameter | Test Method |

Mechanical impurities | % | 无 | GB/T511 |

Demulsibility number | Min | ≤15 | GB/T7305 |

water | % | no | GB/T260 |

Cleanness-degree | grade | ≤6 | NAS1638 |

gas content | % | ≤0.1 | GB/T423 |

Filter precision | um | 5-10 | |

TY-G Series Hydraulic Oil Filtration Machine Technical Parameters

model item | unit | TY-G20 | TY-G30 | TY-G50 | TY-G80 | TY-G100 | TY-G150 | TY-G200 | TY-G300 | ||

flow | L/min | 20 | 30 | 50 | 80 | 100 | 150 | 200 | 300 | ||

working vacuum | Mpa | -0.08~-0.096 | |||||||||

working pressure | Mpa | ≤0.5 | |||||||||

working temperature | ℃ | ≤10~80 freely adjustment | |||||||||

power | V | 380-480V/50-60Hz Three-phase four-wire(Customizable as required) | |||||||||

electric heating power | KW | 24 | 30 | 36 | 42 | 54 | 66 | 72 | 90 | ||

total power | KW | 26 | 33 | 39 | 45 | 57 | 72 | 86 | 105 | ||

inlet/outlet pipe | mm | Φ25 | Φ32 | Φ42 | Φ42 | Φ48 | Φ48 | Φ50 | Φ60 | ||

weight | Kg | 480 | 550 | 600 | 1050 | 1150 | 1450 | 1600 | 2200 | ||

dimension | L | mm | 1150 | 1350 | 1400 | 1500 | 1550 | 1550 | 1600 | 1650 | |

w | mm | 910 | 1000 | 1100 | 1300 | 1350 | 1350 | 1400 | 1450 | ||

H | mm | 1550 | 1600 | 1650 | 1750 | 1800 | 1850 | 1900 | 2000 | ||