Ⅰ.TY-B Series Explosion-proof Vacuum Oil Purifier Usage:

The explosion-proof vacuum oil purifier is widely used in the hydrogenation cracking plant, the flammable and explosive areas,etc.It is not limited in oil purify on lubricant oil, turbine oil, hydraulic oil and insulating oil, but also be special designed for the environment that needs all explosion-proof measurements.

There are 2 grades on anti-explosion, that is ExdiaⅡBT4 and ExdeibⅡCT4. Our device can satisfy the high requirements in anti-explosion grade, and ensure the reliability and safety on oil purifier in the flammable and explosive areas.

Ⅱ. TY-B Series Explosion-proof Vacuum Oil Purifier Features:

2.1 All explosion-proof measurements make sure the safety in flammable and explosive areas.

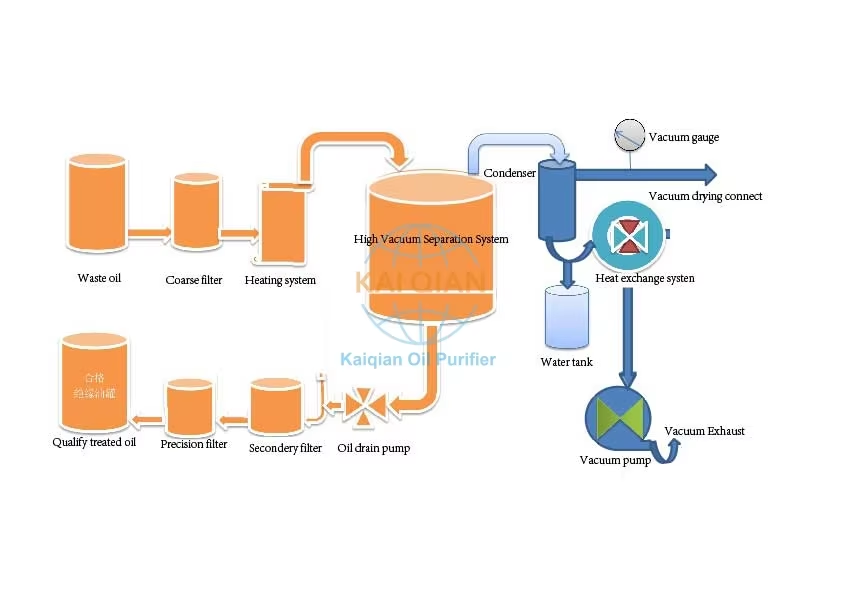

2.2 The application of vacuum flash separation technology and the evaporation on steps technology.

It can separate the moisture effectively and with high demulsification capacity, then the turbine oil would meet the using standard soon.

2.3 The all anti-explosion measurements take use of the safe and reliable recycling carbon fiber heating technology make the average heating and stable temperature while reducing energy consumption

2.4 The application of multi-level precision oil filter element can remove all kinds of impurities, gather large amount of pollutants, use for a long time and can be used repeatedly by washing.

2.5 The use of anti-explosion scan gradually defoaming technology make sure the device not oil injection and run stably in working.

2.6 The use of advanced oil-level control system and overload pressure protection setting, to ensure the safe operation of the machine.

2.7 The use of air-cooled and medium-condensed heat exchange device, can convert the fog into liquid quickly.

2.8 The use of advanced explosion - proof electronic liquid level control system make the controlling become all automatic.

2.9 The online and offline oil purifier on all anti-explosion grade oil in the turbine or the compressor.

2.10 Control system; the optimized design of the control interlock protection device and phase-sequence protection are the systems to ensure a long time reliable operation of the whole machine. Besides the automatic pressure alarm shutdown system, automatic overload protection system, automatic constant temperature system , the automatic anti-fuel injection protection and many other advanced technology guaranteed the full-automated equipment works safely.

Treated Oil Index by TY-B Series Explosion-proof Vacuum Oil Purifier

Items | After treatment | Test method |

Mechanical impurity | No | GB/T511 |

Water content in oil | No trace | GB/T260 |

Gas content in oil | ≤0.1 | GB/T423 |

Cleanliness | ≤Grade 6 | NAS1638 |

Filtration accuracy | 3—5um | |

TY-B Series Explosion-proof Vacuum Oil Purifier Technical parameters

models Items | Unit | TY-B20 | TY-B30 | TY-B50 | TY-B80 | TY-B100 | TY-B150 | TY-B200 | TY-B300 | |

Flow rate | L/min | 20 | 30 | 50 | 80 | 100 | 150 | 200 | 300 | |

Working vacuum | Mpa | -0.08~-0.096 | ||||||||

Working pressure | Mpa | ≤0.5 | ||||||||

Working temp. | ℃ | 10-80 Adjustable setting | ||||||||

Power supply | V/HZ | 380-480V/50-60Hz Three-phase four-wire(Customizable as required) | ||||||||

Total power | KW | 15~200 | ||||||||

Pipe diameter | Mm | Φ25 | Φ25 | Φ32 | Φ38 | Φ45 | Φ45 | Φ48 | Φ65 | |

Weight | Kg | 385 | 450 | 550 | 600 | 800 | 850 | 1000 | 1200 | |

Dimension | L | mm | 1350 | 1400 | 1450 | 1500 | 1550 | 1550 | 1700 | 1850 |

W | mm | 850 | 900 | 1000 | 1100 | 1150 | 1150 | 1450 | 1450 | |

H | mm | 1600 | 1650 | 1700 | 1700 | 1750 | 1800 | 1850 | 1910 | |

Note: the size and weight of equipment with the technology progress slightly adjusted. (the device is closed, opaque type also can be produced according to customer requirements)