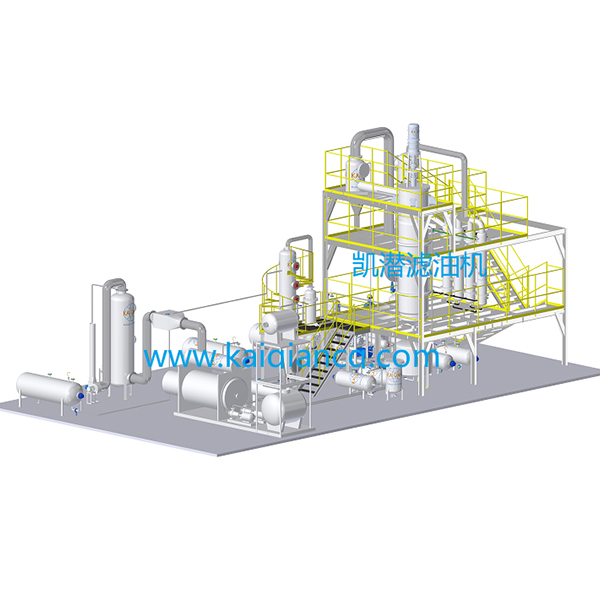

Ⅰ. Used Oil Distillation Plant Process

It adopts high vacuum, atomization and flash distillation technology ,with below features :

1.1 Low working temperature (much lower than the boiling point), high vacuum (no load ≤ 5Pa), short heating time (in seconds), high efficiency separation, etc. Especially suitable for substance separation with high boiling point, heat sensitivity and easy oxidation .

1.2 It can remove low molecular substances (deodorization), heavy molecular substances (decolorization) and remove impurities in the mixture effectively.

1.3 The separation process is the physical separation process, which well protected the oil without be polluted secondary, especially for maintaining the oil quality when extracting.

1.4 With high degree of separation and high vacuum molecular distillation technology, which is more efficiency than the traditional distillation and ordinary thin film evaporator.

1.5 With specialized chemical catalysts and additives, even if under normal pressure, when the waste oil is heating up to 400 ºC, there will be no obvious oil cracking. while under normal pressure, the oil begin to carbonization and coke when the waste oil heating up to 300 ºC without any catalysts, so the recycling oil quality will be reduced and the recovery rate will be decreased too. Because there are much colloid, asphalt, free carbon and other impurities in the waste engine oil, only by catalysts, it can prevent these substances from coking effectively, guaranteeing prolong the machine's life time and improving the oil recovery rate of the waste oil.

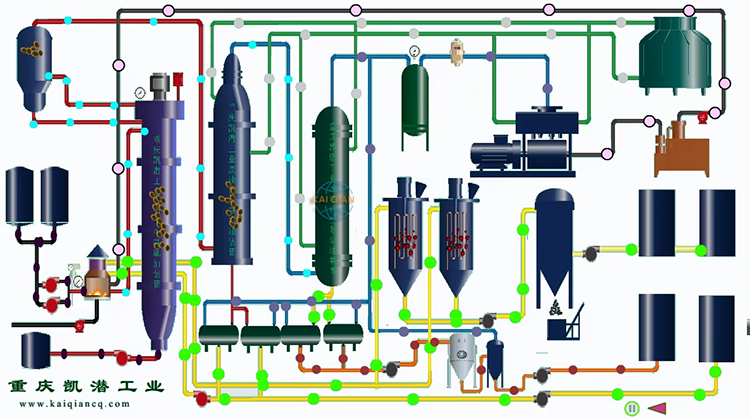

Ⅱ. Used Oil Distillation Plant Process Principle

Oil separation according to the different distillation temperature(liquid-liquid separation), we can get light gasoline/diesel,light base oil, heavy base oil .

2.1 When the oil heated to 180-270ºC,300-500Pa vacuum degree ,light gasoline/diesel components will be pulled out ;

2.2 When the oil heated to 280-300ºC,200-300Pa vacuum degree ,light base oil components will be pulled out ;

2.3 When the oil heated to 300-350ºC,20-50Pa vacuum degree ,heavy base oil components will be pulled out .Cut fractions through condensing then collect to oil tanks .

2.4 The residual oil, light component and extracted oil produced during the process are sold as the by-products of industrial fuel oil.

2.5 Waste oil distillation plant and auxiliary facilities are all sealed, tail gas is collected , and combustion in heating furnace .There is no exhaust in production .

2.6 Our technology no need to pretreat the waste oil material ,without acid alkaline wash and clay process ,no waste residue discharge .

2.7 The waste oil material contains water about 3-5%,it will distilled and condensed during process .There also has 2~3% steam water will be condensed during later refining process .After aeration flotation, the two parts of the oily water can be discharged into the sewage pipe line in the park.

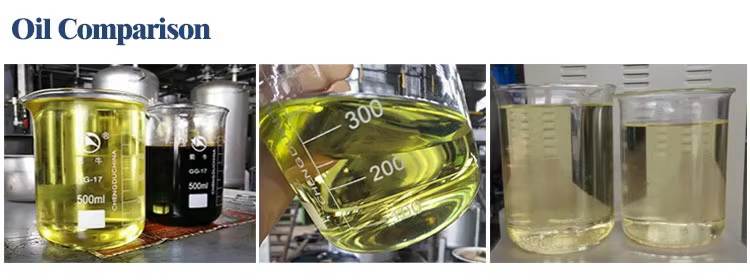

Ⅲ. Tyre Oil and Plastic Oil Distillation Equipment Refined Oil Index

NO. | Item | Test Method | Refined Oil Index | Standard Value |

01 | Viscosity(15℃) | ASTM D1298 | 0.84kg/L | .....kg/L |

02 | Viscosity index (40℃) | ASTM D445 | 3.36cst | 1.6-5.8cst |

03 | Pour Point | ASTM D97 | -19℃ | ≥0℃ |

04 | Flash Point(open) | ASTM D93 | 60℃ | ≥55 |

05 | Water Content | ASTM D95 | Trace%vol | ≤Trace %vol |

06 | Sulfur | ASTM D1226 | 0.15%Wt | 0.2%Wt |

07 | color | Yellow / transparent / Pale yellow / transparent | ||

Ⅵ. Pyrolysis Oil Distillation Equipment Models and Specifications

Model designation | Unit | KTS-C5 | KTS-C15 | KTS-C20 | KTS-C30 | KTS-C50 | KTS-C100 | |

Handling Capacity | T/D | 5 | 15 | 20 | 30 | 50 | 100 | |

Working Pressure | Mpa | ≤0.5 | ||||||

Working vacuum | pa | -5~ -20 | ||||||

Temperature | ℃ | ≤350 | ||||||

Working Noise | dB(A) | ≤85 | ||||||

The power | V | 380-480V/50-60Hz Three-phase four-wire(Customizable as required) | ||||||

Total Power | KW | 80 | 120 | 125 | 140 | 180 | 210 | |

Cooling Water | M³ | 35 | 40 | 50 | 60 | 80 | 160 | |

Weight | T | 16 | 19 | 22 | 26 | 46 | 56 | |

Dimension | L | m | 15 | 17 | 17 | 25 | 35 | 45 |

W | m | 4 | 6.5 | 10 | 12 | 16 | 20 | |

H | m | 6 | 6 | 6 | 6 | 6.5 | 8 | |

Notes | 1.We can customize 150 -300TPD equipment as required 2.Diesel and natural gas heating method will be more economical. | |||||||