Ⅰ. Tyre Pyrolysis Oil Distillation Plant Application

This machine widely used in recycle tyre/tire oil into diesel, plastic oil into diesel and other pyrolysis oils into diesel. The waste oil distillation plant adopts high vacuum distillation process, it can convert waste oil into diesel, low cost, 85-95% high recovery rate, environmental and energy saving. The output diesel can be used as diesel fuel(not the standard diesel), it can be used in factories or big vehicles.

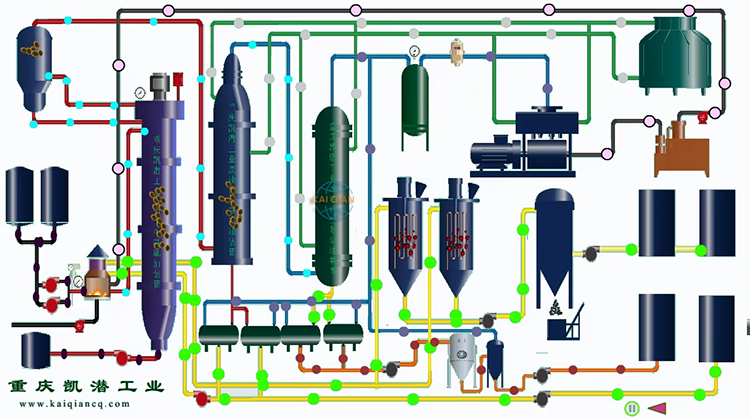

Ⅱ. Tyre Pyrolysis Oil Distillation Plant Working Principles

It adopts high vacuum distillation, thin film flash evaporate distillation technology, which is different from the traditional distillation method separated by boiling point. (eg: separating by traditional technology requires the boiling point difference around 350ºC, while the high vacuum molecular distillation technology only requires about200ºC ), it makes the vacuum liquid - liquid separation come true, also with reflux tower to make oil quality better, with distillation tower to separate oil into different lines.

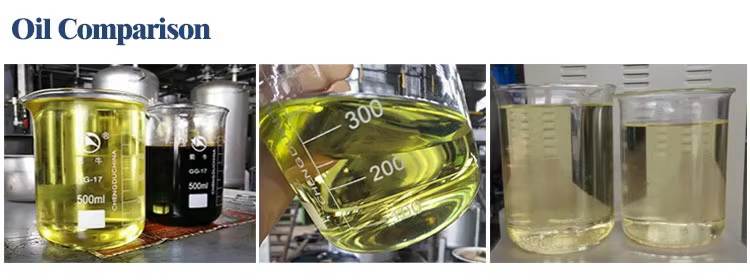

Ⅲ. Tyre Pyrolysis Oil Distillation Plant Refined Oil Index

NO. | Item | Test Method | Refined Oil Index | Standard Value |

01 | Viscosity(15℃) | ASTM D1298 | 0.84kg/L | .....kg/L |

02 | Viscosity index (40℃) | ASTM D445 | 3.36cst | 1.6-5.8cst |

03 | Pour Point | ASTM D97 | -19℃ | ≥0℃ |

04 | Flash Point(open) | ASTM D93 | 60℃ | ≥55 |

05 | Water Content | ASTM D95 | Trace%vol | ≤Trace %vol |

06 | Sulfur | ASTM D1226 | 0.15%Wt | 0.2%Wt |

07 | color | Yellow / transparent / Pale yellow / transparent | ||

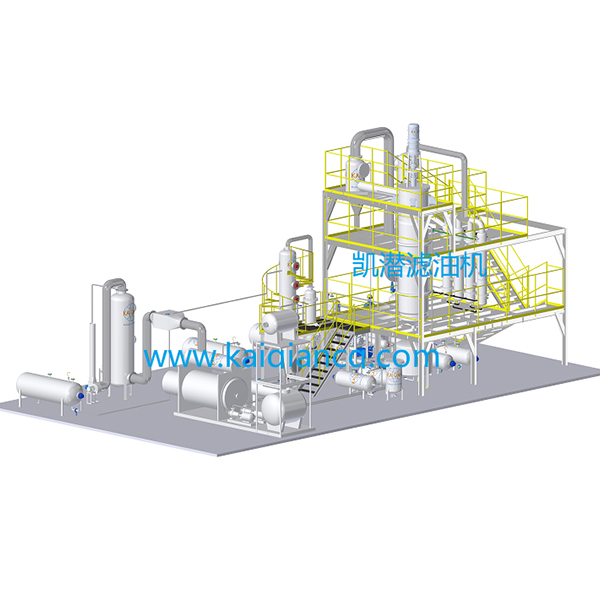

Ⅵ. Tyre Pyrolysis Oil Distillation Plant Models and Specifications

Model designation | Unit | KTS-C5 | KTS-C15 | KTS-C20 | KTS-C30 | KTS-C50 | KTS-C100 | |

Handling Capacity | T/D | 5 | 15 | 20 | 30 | 50 | 100 | |

Working Pressure | Mpa | ≤0.5 | ||||||

Working vacuum | pa | -5~ -20 | ||||||

Temperature | ℃ | ≤350 | ||||||

Working Noise | dB(A) | ≤85 | ||||||

The power | V | 380-480V/50-60Hz Three-phase four-wire(Customizable as required) | ||||||

Total Power | KW | 80 | 120 | 125 | 140 | 180 | 210 | |

Cooling Water | M³ | 35 | 40 | 50 | 60 | 80 | 160 | |

Weight | T | 16 | 19 | 22 | 26 | 46 | 56 | |

Dimension | L | m | 15 | 17 | 17 | 25 | 35 | 45 |

W | m | 4 | 6.5 | 10 | 12 | 16 | 20 | |

H | m | 6 | 6 | 6 | 6 | 6.5 | 8 | |

| Notes | 1.We can customize 150 -300TPD equipment as required 2.Diesel and natural gas heating method will be more ceonomical | |||||||