How to Purify Used Engine Oil?

Writer: Kaiqian Oil Purifier Release time:2024-06-18 17:09 Clicks:

Engine oil is essential for the operation of internal combustion engines as it lubricates moving parts, reduces friction, and helps keep the engine cool.

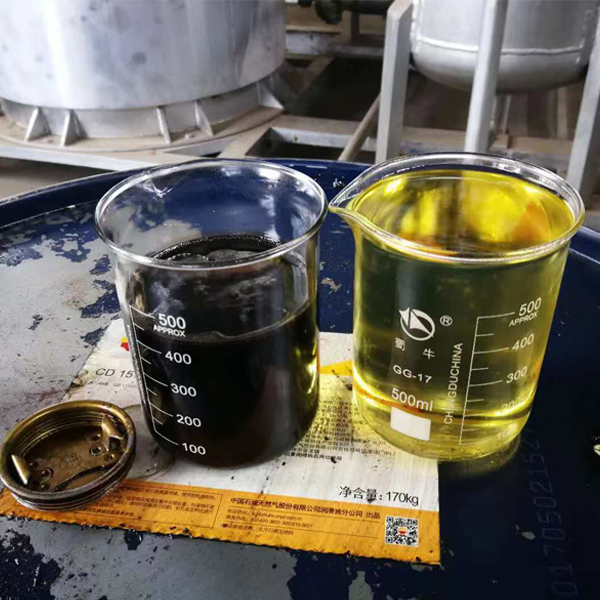

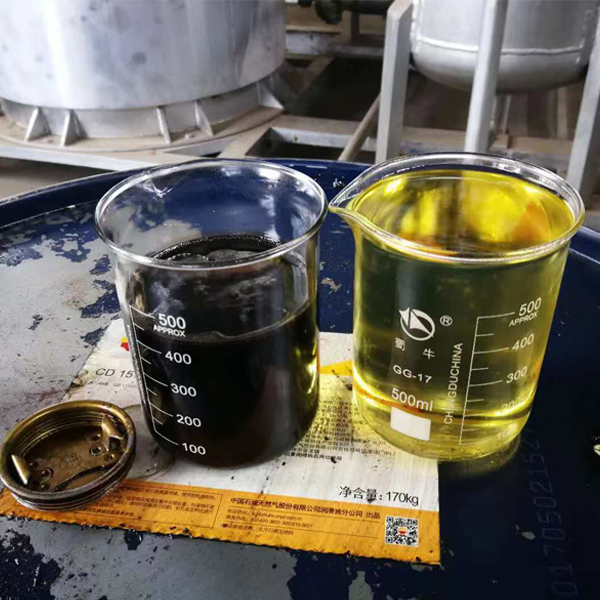

Over time, engine oil accumulates contaminants such as dirt, metal particles, and combustion by-products, which diminish its effectiveness.

Instead of discarding used engine oil, purifying and recycling it can be both environmentally friendly and cost-effective. This article explores the various methods and processes involved in purifying used engine oil.

Understanding the Contaminants

Before diving into the purification process, it's essential to understand the types of contaminants that need to be removed from used engine oil. These contaminants typically include:

Particulate Matter: Dust, dirt, and metal particles from engine wear.

Water and Coolant: Moisture from condensation and coolant leaks.

Oxidation Products: Varnish and sludge are formed due to oil oxidation.

Chemical Contaminants: Fuel residues, acids, and other chemical compounds.

The Importance of Purifying Used Engine Oil

Purifying used engine oil offers several significant benefits:

Environmental Protection: Properly disposing of or recycling used oil prevents soil and water contamination.

Resource Conservation: Recycling oil reduces the demand for new oil production, conserving natural resources.

Economic Savings: Recycled oil can be re-refined and reused, reducing the need to purchasenew oil.

Methods of Purifying Used Engine Oil

Several methods can be employed to purify used engine oil. These methods range from simple filtration processes to more complex chemical treatments.

1. Filtration

Filtration is one of the most straightforward methods for removing solid particles from used engine oil. This process involves passing the oil through a filter medium that traps contaminants while allowing the clean oil to pass through.

Types of Filtration

Simple Filtration: Using standard oil filters to remove large particles.

Centrifugal Filtration: Utilizing centrifugal force to separate particles based on their density.

Vacuum Filtration: Employing a vacuum to pull oil through fine filters, capturing smaller particles.

2. Sedimentation

Sedimentation relies on gravity to separate heavier particles from the oil. The used oil is allowed to sit undisturbed in a container, enabling the denser particles to settle at the bottom. This method, while simple, is often used in conjunction with other purification techniques to improve efficiency.

3. Distillation

Distillation involves heating the used oil to vaporize it and then condensing the vapor back into liquid form. This process can effectively remove water, light hydrocarbons, and other volatile contaminants.

Steps in Distillation

Heating: The used oil is heated in a distillation column.

Vaporization: Contaminants with lower boiling points vaporize first.

Condensation: The vapor is cooled and condensed back into a purified liquid.

4. Chemical Treatment

Chemical treatment involves adding specific chemicals to the used oil to neutralize or remove contaminants. Common chemicals used include acids, alkalis, and coagulants.

Types of Chemical Treatments

Acid-Base Neutralization: Neutralizing acidic or basic contaminants with corresponding chemicals.

Coagulation: Adding coagulants to aggregate fine particles into larger clumps, which can then be filtered out.

Clay Treatment: Using activated clay to adsorb impurities and contaminants from the oil.

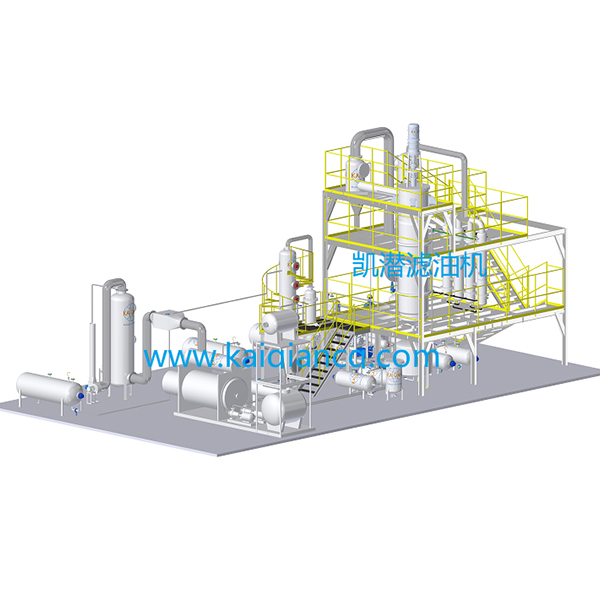

5. Vacuum Distillation

Vacuum distillation is a more advanced form of distillation performed under reduced pressure. This method lowers the boiling point of the oil, allowing it to be distilled at lower temperatures, which prevents thermal degradation of the oil.

Advantages of Vacuum Distillation

6. Hydrotreating

Hydrotreating is a refining process that uses hydrogen gas to remove impurities such as sulfur, nitrogen, and oxygen compounds from the used oil. The process also saturates unsaturated hydrocarbons, improving the stability and performance of the recycled oil.

Process of Hydrotreating

Hydrogen Addition: Hydrogen gas is mixed with the used oil.

Catalytic Reaction: The mixture passes over a catalyst bed, promoting chemical reactions that remove impurities.

Separation: The purified oil is separated from the reaction by-products.

7. Ultrafiltration

Ultrafiltration utilizes a semi-permeable membrane to separate fine particles, emulsified water, and other contaminants from the used oil. The membrane allows only clean oil molecules to pass through, blocking larger impurities.

Benefits of Ultrafiltration

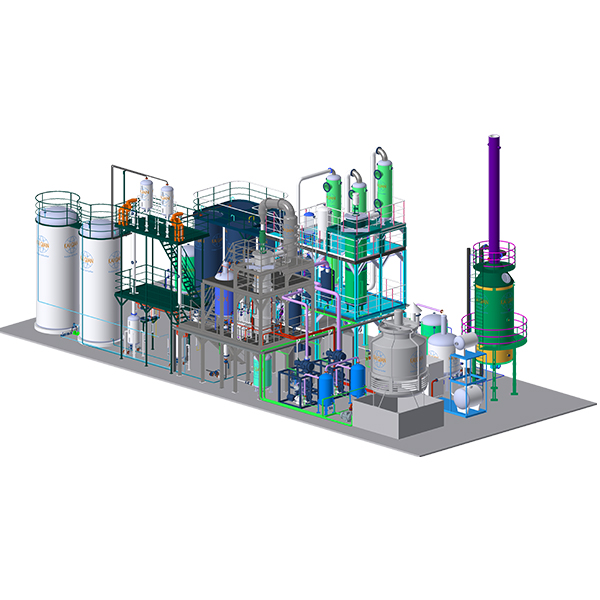

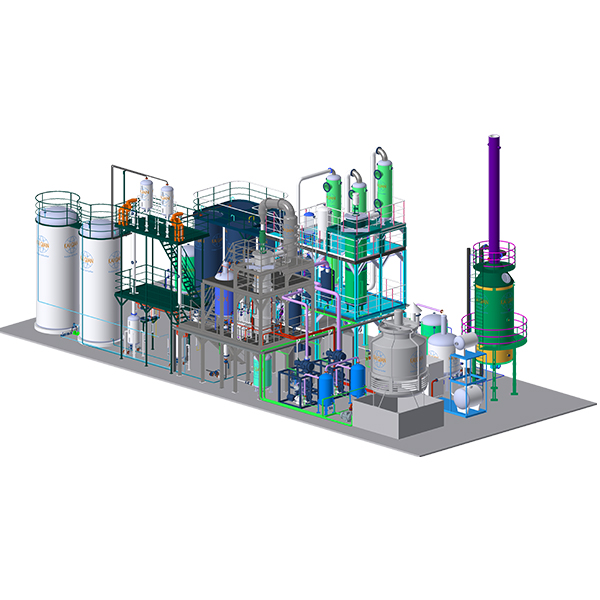

Combining Methods for Optimal Results

While each of these methods can be used individually, combining them often yields the best results. For example, a multi-stage process might involve sedimentation to remove heavy particles, followed by filtration to capture finer particles, and then chemical treatment to neutralize remaining contaminants.

Example of a Multi-Stage Purification Process

Pre-treatment involves sedimentation to settle heavy particles.

Filtration: Centrifugal filtration is used to remove large solids.

Chemical Treatment: Adding coagulants to aggregate fine particles.

Vacuum distillation is a process used to remove water and volatile impurities.

Final Filtration: Ultrafiltration is used to ensure high purity.

Safety and Environmental Considerations

When purifying used engine oil, it is crucial to consider safety and environmental factors:

Handling Chemicals: Ensure proper handling and storage of chemicals used in the purification process to prevent accidents and spills.

Waste Disposal: Dispose of waste materials, such as sludge and spent filters, according to local regulations to minimize environmental impact.

Personal Protective Equipment (PPE): Use appropriate PPE, such as gloves and goggles, to protect against exposure to hazardous substances.

Conclusion

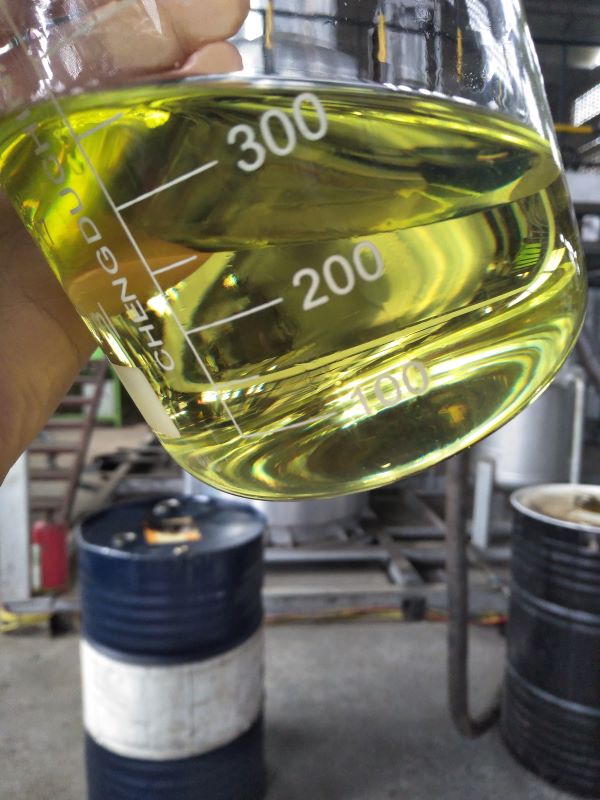

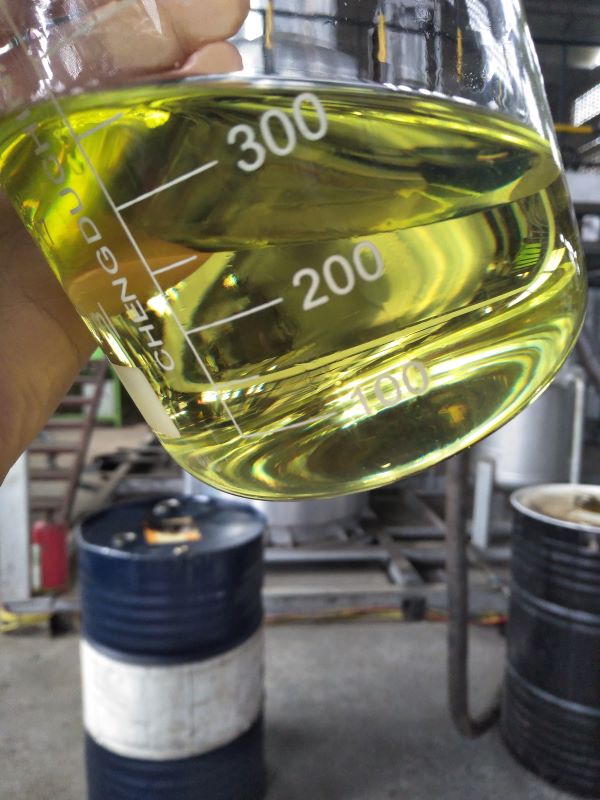

Purifying used engine oil is a valuable practice that contributes to environmental protection, resource conservation, and economic savings.

Various methods, ranging from simple filtration to advanced chemical treatments and vacuum distillation, can be employed to remove contaminants and restore the oil's effectiveness.

By understanding and implementing these purification techniques, individuals and industries can play crucial roles in promoting sustainable practices and reducing the ecological footprint of engine oil usage.

简体中文

简体中文

English

English

Français

Français

Русский язык

Русский язык

Polski

Polski

日本語

日本語

ภาษาไทย

ภาษาไทย

Deutsch

Deutsch

Português

Português

español

español

Italiano

Italiano

한어

한어

Tiếng Việt

Tiếng Việt

Pilipino

Pilipino

بالعربية

بالعربية

বাংলা

বাংলা

IndonesiaName

IndonesiaName

ກະຣຸນາ

ກະຣຸນາ

Türkçe

Türkçe

简体中文

简体中文

English

English

Français

Français

Русский язык

Русский язык

Polski

Polski

日本語

日本語

ภาษาไทย

ภาษาไทย

Deutsch

Deutsch

Português

Português

español

español

Italiano

Italiano

한어

한어

Tiếng Việt

Tiếng Việt

Pilipino

Pilipino

بالعربية

بالعربية

বাংলা

বাংলা

IndonesiaName

IndonesiaName

ກະຣຸນາ

ກະຣຸນາ

Türkçe

Türkçe